2020 was a year full of challenges and uncertainty and the economic impact of the pandemic and the related market turmoil was (and will continue to be) felt by all industries. Changes and difficult decisions concerning prices were evident throughout the packaging industry, but Akomex Group, who were also facing these difficult decisions, acted by continuously optimizing its production processes. Thanks to this, to date the price increases have been absorbed but unfortunately, as a result of many complex global factors, we have now found ourselves in a position where an increase in our costs is inevitable.

Analysis of reasons

The analysis of why packaging prices have increased is difficult, due to the very nature of the industry and the complexity of the market. For a very long time, we have tried to compensate the price increases from our own budget in order to support our customers in these difficult circumstances. Today, due to the continued increase in production costs (raw materials, exchange rates, transport, auxiliary materials, electricity, labour costs), we have been forced to increase our prices. This is not something that we wanted to implement but it is a necessary action if we want to avoid sudden disruptions in the supply chain – says Grzegorz Lajca, President of the Management Board of Akomex Group.

Waste paper prices increase

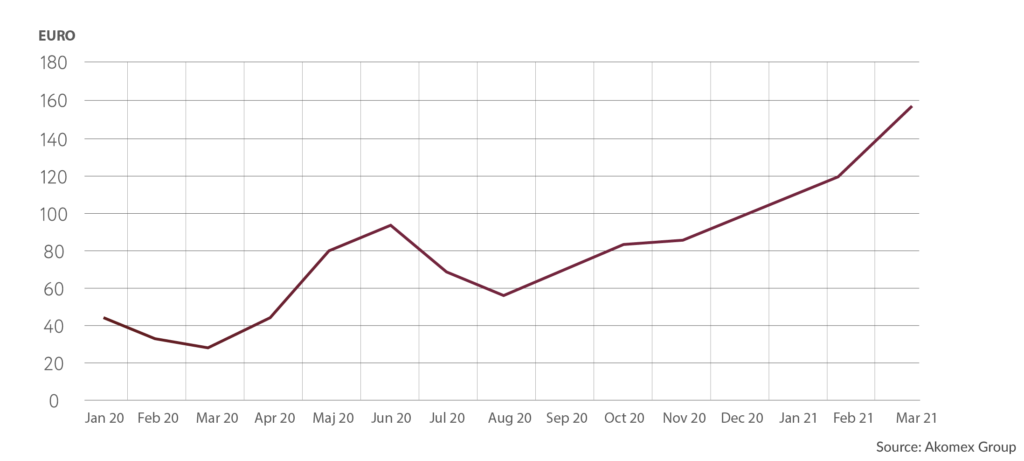

One of the main factors which has led to an increase in packaging prices, is the continued increase in waste paper costs since August 2020. The current value, almost EUR 160 per ton with significant fluctuations of the euro exchange rate, results in not only an increase in the value of cardboard, but also its availability. This is influenced by the dramatic increase in the tonnage of raw material exported to China over the last year. According to independent sources, the amount in 2021 will reach 2 million tons and unfortunately, this will not improve in the future. This will result in further increases and this is something that is already being communicated due to the cost of grey paper waste in Germany.

Paper factories modify prices

The Pulp Mills are already communicating two key issues. Firstly, there is a talk of extended lead times for the production of raw materials. Secondly, there will be price increases for quality boards (GC2, GC1). Another aspect is that, although we are a large manufacturer, paper factories who have seen a dramatic increase in waste paper prices, are having to adjust their costs to us – to date these prices have remained at a relatively balanced and stable level. Our priority is to maintain the continuity of the supply chain for our clients, so we have no alternative but to accept these changes – says Grzegorz Lajca, President of the Management Board of Akomex Group.

We always try execute our customers’ orders using alternative raw materials (from the range approved by you) or using sub-optimal formats – which also has an impact on the increased price of the product – he adds.

The progressive integration trend in the paper manufacturing market is also important, so further price adjustments can be expected. It is also worth taking into account how the Paper Mills currently fulfill orders – stock cannot be reserved and orders need to placed well in advance, which is a result of the availability of raw materials. These factors have a direct impact on the ‘Stock Ordering’ process. Both the board converters and their manufacturing clients will now start to require 3 month forecasts (minimum) in order to guarantee availability – No forecast, no board!!

Industry under price pressure

The Packaging Industry is currently under real pressure. It is not just down to the cost of waste paper, foil, adhesives etc along and the dramatic increase in the price of the raw materials used for their production, but it is also the rise in the cost of labour, energy, alcohol, pallets and other auxiliary materials. For example: in February 2021, the price of glue used for the lamination process, increased by as much as 15%, and from April 2021, we face a further increase of 10%. Also transport and the associated ‘packing materials’ have become more expensive. 2020 was an extremely difficult year for the Transport Industry and so this year we will see an attempt by many to recoup the losses by increasing their prices, which will obviously have an impact on the cost of delivering the final product.

Care for the health of employees in times of pandemic

Coronavirus has also been a major cause in bringing about these price increases. The need to introduce Covid related restrictions and regulations meant that companies, including Akomex Group, saw a significant increase in expenditure on cleaning and protection products in order to eliminate virus emissions and ensure the safety of our staff. This additional expenditure helped to ensure the continuity of the supply chain and allowed both of the Akomex sites to operate without disruption, but has caused a significant increase to our Budget Allowance.

We do what we can

The relationship with our clients have always been the main priority to Akomex Group. Despite changing circumstances, the company has tried to ensure that our offer has remained consistent in spite of significant market changes. An example of this, has been our ability to keep any price changes to a minimum and where ever possible, we have ‘absorbed’ them and not passed on to our clients. Unfortunately though, given the recent market developments, it is now necessary for us to adjust the price of our manufactured products so they now fall in line with the increases.

It is also worth noting that there is still uncertainty in the guaranteed delivery of certain raw materials and this to some extent, is out of our control. To try and alleviate this potential problem and ensure continuity of production we are buying and holding stock of certain raw materials, but this again is adding additional and higher costs over and above our planned budget.

Future prospects

It is impossible to gauge how and when the cost of packaging will stabilize as it will depend on a number of different factors. Despite this uncertainty, Akomex Group will continue to look at ways of optimizing our production / pre-production processes, to try and maintain price stability and continuity of supply, ensuring continued close co-operation at every stage with our clients. We will endeavor to maintain our prices at a satisfactory level, despite the dramatic increase in raw materials and other associated costs that have a direct impact on the manufacture of packaging products.